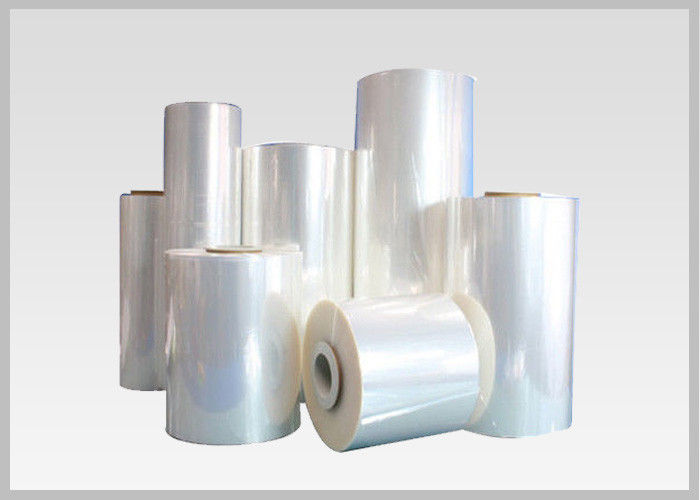

Beverage Bottle PETG Shrink Sleeve Film 78% Shrinkage Recyclable, 30-80mic Thickness

1. Introduction

PETG – Polyproplyene Terephthalate Glycol (PETG) is an amorphous plastic resin of the polyester family. The Heat shrink film produced by PETG is a high density film with a high strength ratio and excellent clarity. Due to its 80% shrinkage, highest among all shrink sleeve material, PETG is an ideal solution for container shrink film that has complex geometries and requires superior printability.

Compared to other material, PETG Shrink film is much more environmentally friendly making it a perfect solution for companies looking to switch from more harmful materials such as PVC. The heat shrink film could be used to pack with PET containers or bottles, provided that can cut down recycling cost. Since PETG’s shrinkage occurs at a lower temperature than material like PVC and OPS, there is the added benefit of higher energy efficiency and productivity.

2. Features

Polyester (Polyethylene Terephthalate with Glycol)

1) High clarity

2) Shrink up to 75%

3) Chemical resistance

4) Recyclable

5) Less MD growth than PVC

3. Specification

1) Thickness: 30-70μ

2) Width: 450-1200mm

3) shrinkage: high and medium shrinkage

4) Standard export pallet packing

5) Applications: electrical insulation

4. Technical Data Sheet

| No |

Test Item |

UNIT |

Standard |

Test Result |

Decide |

| 1 |

(Average thickness deviation) |

μm |

±3 |

0 |

Qualified |

| 2 |

TENSILE STRENGTH |

(MD) |

MPa |

≥42 |

65.8 |

Qualified |

| (TD) |

MPa |

≥142 |

231 |

| 3 |

ELONGATION |

(MD) |

% |

≥300 |

591 |

Qualified |

| (TD) |

% |

≥35 |

55 |

| 4 |

(Elasticity Modulus) |

(MD) |

MPa |

≥1500 |

3269 |

Qualified |

| (TD) |

MPa |

≥3000 |

7370 |

| 5 |

HEAT SHRINKAGE |

(MD) |

% |

≤5.0 |

2.3 |

Qualified |

| (TD) |

% |

60~78 |

66 |

| 6 |

(HAZE) |

% |

≤7.0 |

2.2 |

Qualified |

| 7 |

C.O.F |

(IN/OUT) |

dynamic friction coefficient |

/ |

≤0.50 |

0.47 |

Qualified |

| 8 |

WETTING TENSION |

mN/m |

≥38 |

≥38 |

Qualified |

| 9 |

Density |

g/cm3 |

1.32±0.3 |

1.46 |

Qualified |

5. Application

1) Full or partial body shrink sleeves;

2) Full or partial body roll sleeves;

3) Tamper-evident band;

4) Wine capsules and disk plates;

5) Pressure-sensitive shrink labels;

6) Promotion combining pack

6. Package

7. Production Machine

8. Transportation

1) Over the sea: The films are suggested to be shipped with reefer container. If less than container loading, the anti-heat material is advised to be used for packing to protect the films.

2) Container over the land: The truck with electronic power should be used for moving the container between port and factory to keep the reefer container working.

9. Storage

1) The film is suggested to be stored in the warehouse with the temperature below 23℃, if in hot season, installing the air conditioner or other solution to cool down the warehouse should be taken.

2) The film storage period is 3 months. Please try to use up film within 3 months while they are at perfect conditions.

10. FAQ:

1) Q: What is your MOQ?

A: Normally our MOQ for each size is 1ton. If you think it is too much, we can discuss according to your requirement in details.

2) Q: Can you offer free sample?

A: Yes, we can provide free samples of 150m - 200m.

3) Q: What is your delivery time?

A: We deliver in 10-20days.

4) Q: Can you accept mixed products in one container?

A: Yes, we accept for sure.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!