Plain And Embossed Vacuum Metallized / Aluminized Paper For Wine Packaging With 68gsm--83gsm

Product Information

| No |

Property |

Unit |

Test Method |

Value |

| 1 |

Grammage |

g/m2 |

GB/T451.2 |

±3 |

| 2 |

Moisture |

% |

GB/T462 |

5.5±1 |

| 3 |

Wet Strength |

MD |

KN/m |

GB/T465.2 |

≥1.0 |

| TD |

KN/m |

GB/T465.2 |

≥0.7 |

| 4 |

Tensile Strength |

MD |

KN/m |

GB/T453 |

≥3.5 |

| TD |

KN/m |

GB/T453 |

≥1.8 |

| 5 |

Wet Tensile Strength |

mN/m |

GB/T14216 |

≥36 |

| 6 |

Break Load |

MD |

mN |

GB/T455.1 |

≥350 |

| TD |

mN |

GB/T455.1 |

≥350 |

| 7 |

Reverse Side COBB (60s) |

g/m2 |

GB/T1540 |

15±5 |

| 8 |

Aluminum Firmness |

% |

_________ |

≥95 |

| 9 |

Alkali Resistance |

S |

_________ |

≤90 |

| 10 |

Gloss(45°) |

% |

GB/T8941.2 |

EMBOSSED≥200 |

| _________ |

_________ |

PLAIN≥300 |

| 11 |

Smoothness |

S |

GB/T456 |

EMBOSSED≥600 |

| _________ |

_________ |

PLAIN≥1000

|

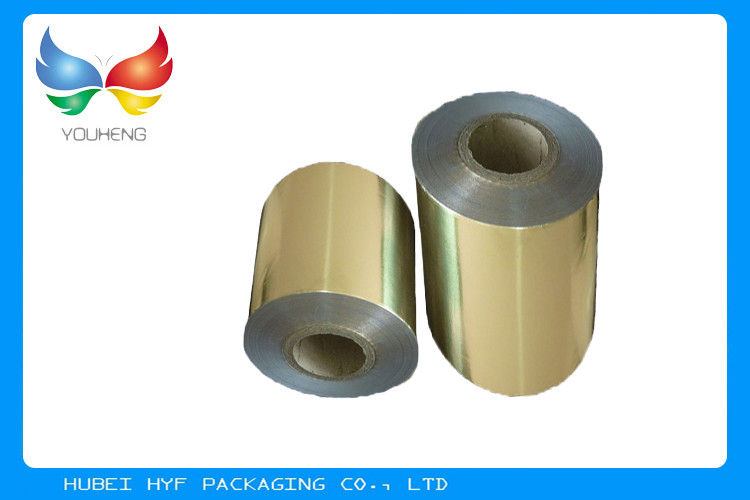

Type: Plain & Embossed

Grammage: 68gsm, 71gsm, 73gsm ( up to you)

Width: 200-2000mm

Length: 2500-4000m

Color: Silver, golden and etc.

Sample: 150-200m

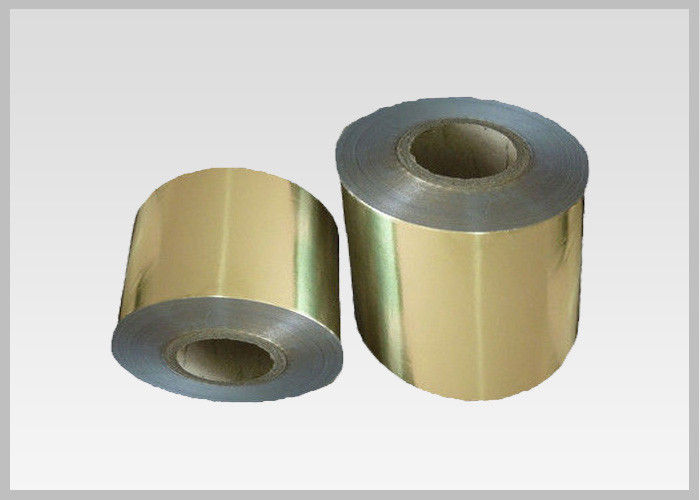

Products Show

Surface Quality

a) The surface have glossy finish, not be oxidized & blackiness.

b) Surface is free from unmetallized spots, scratches, dents, pinholes, bubbles.

c) Suitable for offset printing, rotogravure printing and flexible printing

d) Easy to stick or remove from bottles

e) High water absorbency

f) Excellent properties when use for labels

g) With excellent adhesion ability with ink, the paper remains flat with no rolling of edges

Winding Quality

i) Sufficiently tight so that it does not get telescoped, no wrinkles creases, ripples present.

ii) Free from bagginess, flappiness, no uplifted edge, unflush winding.

iii) The roll is unwound without blocking.

Application

Widely used in beer label, wine, beverages and etc, which has a good performance for printing.

Packaging and Shipping

1. 30% deposit by T/T before producing, balance paid before shipment. And L/C, Western Union accepted.

2. By express. By sea. By air.

FAQ:

1. Do your metallized materials require any preparation (priming) before printing?

No, they don’t, as the board and paper produced by HYF carry a finishing primer ensuring high-quality printing with UV and foil offset alkali proof inks.

2. What are the advantages and disadvantages of printing on the metallized surface of UV-curable inks?

Printing with UV inks is a more versatile and environmentally friendly method for non-absorbent materials. The advantage of this technology is that it requires no anti-set-off powder and the ink dries almost instantly.

However, UV inks are more expensive than foil ones and can be used only for special printing machines that feature extra driers. This makes the process more energy consuming and expensive when using the UV inks.

3. What is the right way to store metallized materials?

Metallized paper and boards should be stored enclosed in their original packaging to ensure a constant humidity indicator.

Before printing, the material should be acclimatized in the production room for at least 2 hours. If the difference between the temperatures of the metal and the room is big, the acclimatization should be prolonged to 24 hours.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!