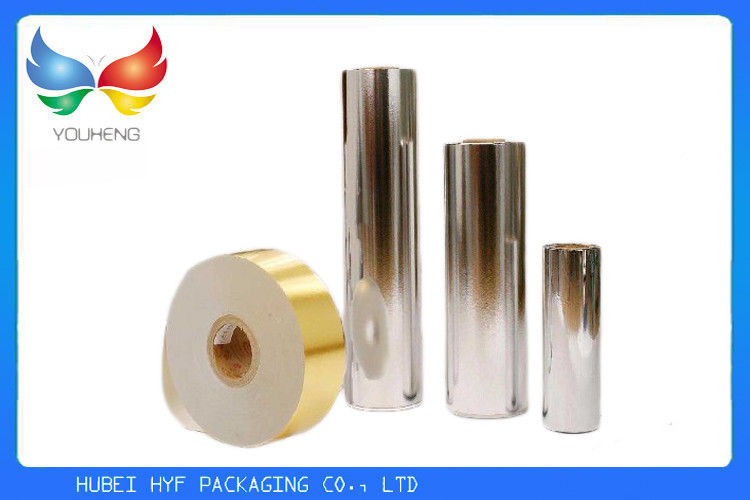

71gsm Waterproof Silver Vacuum Metallized Paper For Wine Label

1. Grammage & Usage

1) 68gsm , 69gsm , 71gsm For beer and alcoholic drinks

2) 73gsm For non-alcoholic drinks

3) 73gsm-gold For food packaging,wrapping

4) 53gsm For cigarette pack underlayer

2. Process of Vacuum Metallized Paper

1.Coated base paper ;

2.Then metalizing 1-3gsm layer on the coated side

3.End coated on metallized layer

3. Features of Vacuum Metallized Paper

1. High glossy,strong metallic looking,perfect metallization evenness,smooth surface,excellent aluminium bonding.

2. With excellent adhesive ability to inks,the paper is plain with no curliness,suitable for offset printing,rotogravure printing and other types of pringtings.

3. Excellent labelability,high water absorption,produce smooth surface after pasted or molded.

4. High alkali penetrability,quick label wash-off speed,excellent wet strength ability.

We are the first company in China that developed the environment-protective technology in vacuum metallizing paper with aluminium,which is recycling and can realize green products'fuction.

4. Technical Data Sheet Of Vacuum Metallized Paper

| Number |

Property |

Unit |

Test Method |

Value |

| 1 |

Grammage |

g/m2 |

GB/T451.2 |

±3 |

| 2 |

Moisture |

% |

GB/T462 |

5.5±1 |

| 3 |

Wet Strength |

MD |

KN/m |

GB/T465.2 |

≥1.0 |

| TD |

KN/m |

GB/T465.2 |

≥0.7 |

| 4 |

Tensile Strength |

MD |

KN/m |

GB/T453 |

≥3.5 |

| TD |

KN/m |

GB/T453 |

≥1.8 |

| 5 |

Wet Tensile Strength |

mN/m |

GB/T14216 |

≥36 |

| 6 |

Break Load |

MD |

mN |

GB/T455.1 |

≥350 |

| TD |

mN |

GB/T455.1 |

≥350 |

| 7 |

Reverse Side COBB (60s)

|

g/m2 |

GB/T1540 |

15±5 |

| 8 |

Aluminum Firmness

|

% |

_________ |

≥95 |

| 9 |

Alkali Resistance |

S |

_________ |

≤90 |

| 10 |

Gloss(45°) |

% |

GB/T8941.2 |

EMBOSSED≥200 |

| _________ |

_________ |

PLAIN≥300 |

| 11 |

Smoothness |

S |

GB/T456 |

EMBOSSED≥600 |

| _________ |

_________ |

PLAIN≥1000 |

5. FAQ

Which paper and board bases are used for producing metallized materials at Golden Elephant?

We only use high quality raw materials of trusted manufacturers.

Wet strength paper: Stora Enso, Aralar;

LWC and Coated paper : Cham Paper Group,Gold East Paper ;

FBB&SBS Ivory board&Duplex Board:Ningbo APP and Sun Paper group Dragons paper .

What are the advantages and disadvantages of printing on the metallized surface of UV-curable inks?

Printing with UV inks is a more versatile and environmentally friendly method for non-absorbent materials. The advantage of this technology is that it requires no anti-set-off powder and the ink dries almost instantly.

However, UV inks are more expensive than foil ones and can be used only for special printing machines that feature extra driers. This makes the process more energy consuming and expensive when using the UV inks.

Do the HYF’s metallized materials require any preparation (priming) before printing?

No, they don’t, as the board and paper produced by Golden Elephant carry a finishing primer ensuring high-quality printing with UV and foil offset alkali proof inks.

What is the right way to store metallized materials?

Metallized paper and boards should be stored enclosed in their original packaging to ensure a constant humidity indicator.

Before printing, the material should be acclimatized in the production room for at least 2 hours. If the difference between the temperatures of the metal and the room is big, the acclimatization should be prolonged to 24 hours.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!