Soft PETG Shrink Film Transparent Blow Clear with High Shrinkage, Low Density

1. Product Description For PETG Shrink Film

POLYESTER(PETG) considered as a kind of ester film met friendly environment, is mainly used to pack with PET containers or bottles, provided that can cut down recycling cost.PETG shrink film is available for a variety of packaging types, sleeves, tamper evidence, extruded roll stock, shrink bags or cap seal according to customers' size.

Many large companies are switching to the versatility and sustainability of PETG over PVC and OPS including Coca-Cola, Pepsi, Nestle, and Unilever, The benefits of PETG shrink film in the consumer markets have well received.

1. Specification Of PETG Shrink Film

| Material |

PETG |

| Thickness |

30 Micron to 80 Micron |

| Width |

450m - 1200mm |

| Length |

3000-4000m |

| Color |

Transparent and any color specified by customers |

| Packing |

Delivered in rolls for automatic machines application or per unit for a manual application |

2. Technical Data Sheet For HYF206MF &HYF206H:

1) HYF206MF--- Mediate Shrink: 60%-70%

| Item |

Unit |

Typical Value |

Testing Method |

| Thickness |

mic |

40, 45, 50, 60 |

ASTM D374 |

| Thickness Tolerance |

% |

±3 |

| Material Yield |

m²/kg |

|

- |

| 40mic |

18.9 |

| 45mic |

16.8 |

| 50mic |

15.2 |

| 60mic |

12.6 |

| Tensile Strength |

MD |

Mpa |

50 |

ASTM D882

v=100mm/min |

| TD |

240 |

| E-Modulus |

MD |

1900 |

| TD |

4300 |

| Elogation At Break |

MD |

% |

430 |

| TD |

39 |

| Heat Shrinkage |

MD |

% |

1 |

ASTM D 1204

90℃/10Sec/Water |

| TD |

65 |

| C.O.F |

us |

- |

0.485 |

ASTM D1894 E |

| uk |

0.43 |

| Haze |

% |

3.65 |

ASTM D1003 |

| Gloss(45°) |

- |

110 |

ASTM D2457 |

| Dyne |

mN/m |

40 |

ASTM D2578 |

| Density |

g/cm³ |

1.32 |

ASTM D792 |

2) HYF206MF--- High Shrink: 70% - 78%

| Item |

Unit |

Typical Value |

Testing Method |

| Thickness |

mic |

40, 45, 50, 60 |

ASTM D374 |

| Thickness Tolerance |

% |

±3 |

| Material Yield |

m²/kg |

|

- |

| 40mic |

18.9 |

| 45mic |

16.8 |

| 50mic |

15.2 |

| 60mic |

12.6 |

| Tensile Strength |

MD |

Mpa |

50 |

ASTM D882

v=100mm/min |

| TD |

240 |

| E-Modulus |

MD |

1900 |

| TD |

4300 |

| Elogation At Break |

MD |

% |

430 |

| TD |

39 |

| Heat Shrinkage |

MD |

% |

0 |

ASTM D 1204

90℃/10Sec/Water |

| TD |

78 |

| C.O.F |

us |

- |

0.485 |

ASTM D1894 E |

| uk |

0.43 |

| Haze |

% |

3.65 |

ASTM D1003 |

| Gloss(45°) |

- |

110 |

ASTM D2457 |

| Dyne |

mN/m |

40 |

ASTM D2578 |

| Density |

g/cm³ |

1.32 |

ASTM D792

|

3. Features For PETG Shrink Film

1) High clarity; low density; good optical properties, soft; cold resistant.

2) Harmless, environmentally friendly, damp-proof, dust-proof.

3) Can protect products efficiently and promote the class of products.

4) It is compatible with both automatic and semi-automatic packaging machines.

5) Non-toxic, odorless, good security, convenient to use.

6) Fast shrinkage under low temperature; good sealing under high speed.

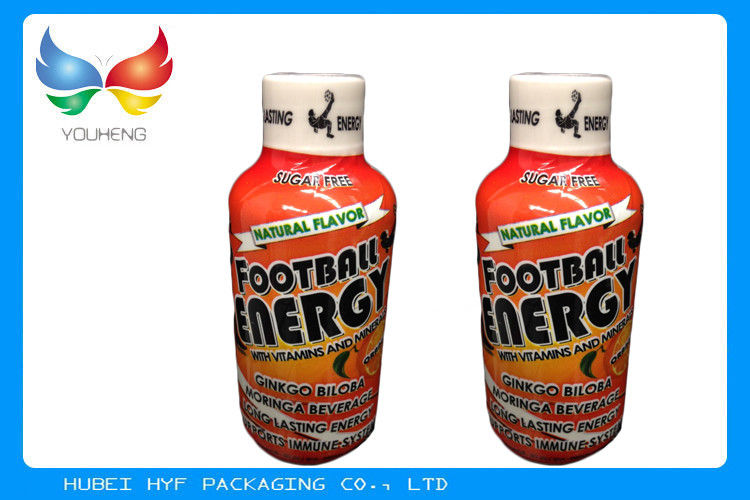

4. Applications For PETGShrink Film

1) Widely for all types of bottles, cups, trays printing.

2) Used for making full body sleeves and containers.

5. Advantages For PETG shrink film

PETG is an amorphous plastic resign of the polyester family. Due to its high shrinkage,

highest among all shrink sleeve material, PETG is an ideal solution for container shrink film that has complex geometries and requires superior printability. Compared to other material, PETG resign is much more environmentally friendly making it a perfect solution for companies looking to switch from more harmful materials.

6. Packaging Of PET Shrink Film

7. Storage Of PETG Shirnk Film

1) Store our PET(G) shrink films below 30℃ in its original packaging;

2) Avoid damages from direct sunlight, high moisture and falling down.

3) Shelf life:6 months.

8. Our Services

9. Favorable Comments

10. FAQ

Q: 1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality.

Mixed samples are acceptable.

Q: 2. What is the lead time?

A: Sample needs 2-3 days prepared; mass production time needs 15-25 days normally.

Q: 3. Do you have any MOQ limit?

A: Our MOQ is 1Tons;

Sea Port: FOB Shanghai

Q: 4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by LCL or FCL by sea or air shipment.

The delivery time according to your quantity.

Q: 5.What information should I let you know if I want to get a quotation?

A: The external size of your products(Thick x Width x Length)

The quantity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!