40 Micron High Clear 52% PVC / 78% PETG Shrink Film Roll For Heat Shrink Labels

There are four well-known types of shrink films: PVC (polyvinyl chloride), PET-G (polypropylene terephthalate glycol), OPS, PLA. PET-G is a high strength film with excellent clarity, good abrasion resistance, moderate permeability, high stability and a wide temperature range.

HYF could provide you PVC shrink film with shrinkage (45%-52%) and PETG shrink film( 60%-70% & 70-78%) in order to satisfy different customers' requirements in different bottles.

1. Introduction For PVC Shrink Film & PETG Shrink Film

| Material |

PVC Shrink Film |

PETG Shrink Film |

| Brief Introduction |

PVC (polyvinyl chloride). PVC is the second most used plastic on the planet, behind polyethylene. PVC film has good shrinking qualities (generally between 40 and 52%), as well as clear and precise rendering, in addition to being very transparent. |

PETG (polyethylene terephthalate glycol). PETG is more expensive than PVC, but it’s the most resistant film with the highest shrinking capability (up to 78%). It’s characterized namely by its superior shine and excellent transparency. |

| Specification |

1) Thickness: 30-70mic 2) Max. Width: 1000mm 3) Shrinkage: 45%-52% |

1) Thickness: 30-70mic 2) Width: 450-1200mm 3) Shrinkage: 60%-70% & 70%-78% |

| Charaters |

1) Excellent Transparency 2) High Shrinking Capability at lower temperature 3) Resistance to Moisture / Oil 4) Good Mechanical Properties 5) Excellent Electrical Insulation Properties 6) Excellent Printability |

1) Excellent printability

2) All-encompassing design

3) Crystal Clarity

4) High shrink rate

5) Halogen-free*

6) Machinerunnability

7) Lower carbonfoot print

|

2. Specification For PVC Shrink Film & PETG Shrink Film

| PVC Shrink Film |

Thickness |

Thickness Tolerance |

Tensile Strength |

Elongtion At Break |

Heat Shrinkage |

| (mic) |

% |

MPa |

% |

% |

| MD |

TD |

MD |

TD |

MD |

TD |

| 30-70 |

±3 |

≥50 |

≥42 |

≥50 |

≥70 |

0~2 |

45~52 |

| PETG Shrink Film |

Thickness |

Thickness Tolerance |

Tensile Strength |

Elongtion At Break |

Heat Shrinkage |

| (mic) |

% |

MPa |

% |

% |

| MD |

TD |

MD |

TD |

MD |

TD |

| HYF206MF |

40,45,50,60 |

±3 |

50 |

240 |

430 |

39 |

1 |

65 |

| HYF206H |

40,45,50,60 |

±3 |

50 |

240 |

430 |

39 |

0 |

78 |

| Test Method |

ASTM D 374 |

ASTM D 374 |

ASTM D882 V=100mm/min |

ASTM D882 V=100mm/min |

ASTM D1204 100℃/10sec/Water |

You could download our detailed technical data sheet here:

PVC-HYF286(1).pdf PETG-HYF206MF.pdf PETG-HYF206H(1).pdf

3. Shrink Curve Comparison For PVC Shrink Film & PETG Shrink Film

4. Advantage & Application For PVC Shrink Film & PETG Shrink Film

| Material |

PVC Shrink Film |

PETG Shrink Film |

| Advantage |

PVC is the most commonly used shrink material in North America and unsurprisingly the one with the lowest overall cost. It has several qualities including excellent shrink capabilities (40% to 52%).

It also has high transparency, renders printing very precisely and is the easiest of all plastics to control during the shrink process. Finally has excellent

seaming properties and is highly resistant to impact.

|

It has the strongest shrink capability (up to 78%). It is important to note that because of this high shrink rate, PETG works well in hot air shrink tunnels but yields best results in steam tunnels.

PETG has better transparency than PVC. PETG is not known to cause health problems. |

| Application |

The PVC shrink films are used for labeling and packing products in various industries like

1) Food & beverage industries: Mineral Water, Soft Drinks, Liquors, Pickles, Jams, Jellies, Fruit Juices, Tea, Coffee, Spices, Ghee, Edible Oils etc. In Bottles/Cans/Jars

2) Printing & Packaging industries

3) Cosmetic & Toiletry industries: Powder, Perfume, Hair Oil, Shampoo etc. in bottles & jars

4) Pharmaceutical industries: Liquid Bottles, Tablet/Powder Containers & Jars

5) Electrical industries

6) Stationery & Writing instrument industry

|

1) Full or partial body shrink sleeves

2) Full or partial body roll sleeves

3) Multi-packs

4) Tamper-evident bands

5) Wine capsules and disk plates

6) Pressure-sensitive shrink labels

|

4. Application For PVC Shrink Film & PETG Shrink Film

5. Our Advantages

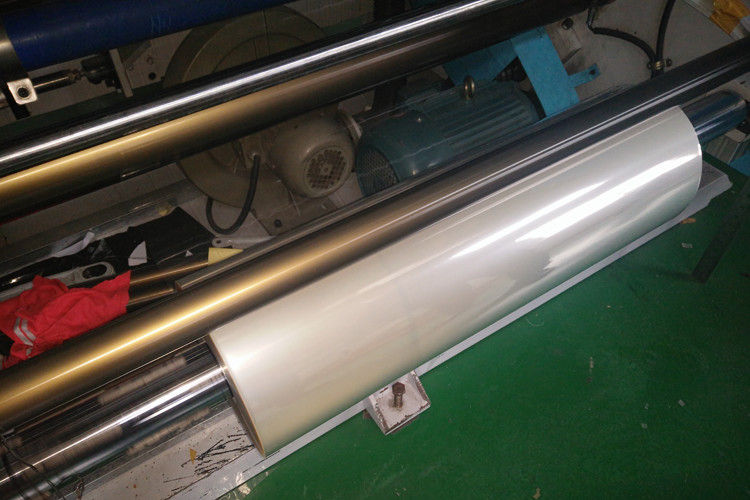

6. Production Lines For PVC Shrink Film & PETG Shrink Film

7. Shrink Sleeve Labels Benefits

The benefits of shrink sleeve labels are numerous, but can be summed up easily: Increased Sales.

It is difficult to argue with the versatility of custom printed packaging and security seal labels rolled into one with added visual branding options. From full body shrink sleeve labels to tamper-evident shrink bands to multi-pack or promotional shrink bands, we can provide you with the tools you need to help increase sales, market share, and consumer confidence in your brand.

1) Visual Branding. Shrink sleeves can be custom printed with full-color photographic images that wrap 360 degrees around the entire container. Without the space limitations of conventional labels, shrink sleeve labels allow for greater creativity in presenting brand identity, special promotions and product information. Revitalize an old brand by showing consumers that a product they thought they knew is worth another try.

2) Security Seal. A full body shrink sleeve can also perform as a tamper-evident security seal on a product container, eliminating the need and the expense of multiple labels and packaging processes.

3) Consumer Confidence. Add an extra layer of confidence in your product by using the inherent transparency of shrink film to create a clear, unprinted window section that allows consumers to view the contents of the package.

4) Durability. Shrink sleeve labels are reverse printed on transparent shrink film, sealing the inks safely behind 40-70 microns of clear film. This means your graphics are protected from the scuffing, marring, or tearing traditional labels are exposed to during transport or while on the store shelves, ensuring your product packaging goes to market in pristine condition.

5) Sustainability. Shrink Sleeves are available in several environmentally friendly shrink films, including the fully biodegradable PLA, or polylactic acid, a corn-based biopolymer. Market your product as sustainable and appeal to an ever more environmentally conscious public.

8. FAQ

1) How can I get the sample?

----We could provide you 200m free sample, but you should pay for the transportation freight of samples, the freight depends on the weight and packing size and your area.

----If you need big roll sample, the sample fee and transportation freight of sample should be paid, the freight depends on the weight and packing size and your area.

2) How do I get a quote for PVC / PETG shrink film?

----We’re glad you asked by email (alice@hyfpack.com) or WhatsApp(008615327161968)! We can get started on building you a quote right away.

3) Which information should be provided by getting a quote?

----Thickness, width, length, shrinkage, quantity

----If you do not know the details, you could tell your requirements, we could give you some suggestions

4) How does HYF package PETG shrink film?

----We pack in the horizontal way. Horizontal packaging the roll is wrapped with polyethylene film and set on plastic end boards. The rolls are then strapped to each other and to the pallet. Finally, each pallet is then stretched wrapped prior to shipment.

5) How should the film be stored?

----Heat shrinkable film is unlike other film substrates. You must take care that the film is stored at or below the temperature suggested preventing premature shrinkage from occurring. Care must also be taken in storing the film after printing, and in shipping film to co-packers or end-users. Some natural shrink information is provided for you on each specification sheet. This goes for all shrinkable film, but especially SBS (styrene) film, which is more susceptible to natural shrinkage issues.

6) How are Shrink Sleeve Labels Applied to Containers?

----The two primary ways to apply shrink sleeve labels is machine shrunk and hand shrunk. Typically machine shrunk is used for larger batches, and hand shrunk is used for smaller ones. Hand shrinking requires a small hand-held heat gun to fit the sleeves onto the containers securely.

7) Why Do Consumers Want Shrink Sleeves?

For consumers, the packaging is the significant differentiator when selecting a brand. Between 40-70 percent of purchasing decisions are made by the consumer on the store shelf. Studies have shown that shrink sleeves combined with contoured containers provide the highest potential for connection with consumers, perceived value, and increased brand loyalty.

9. Trade Terms

Payment: 30% T/T deposit payment in advance, balance shoule be paid before shipment also by T/T. WESTERN UNION, L/C.

Production Lead Time: 15 - 20 days after deposit payment.

Shipping Methods: ocean, railway

FOB Shipping Port: wuhan/ shanghai, mainland China

If you want to deal with EXW/CIF/CNF term instead of FOB, please specify. Otherwise, FOB price will be quoted under inquiry.

10. Our Services

Your inquiry related to our product & price will be replied within 24hours.

Well-trained & experienced staff are to answer all your inquiries in English of course.

Working time: 8:30am - 6:00pm, Monday to Friday (UTC+8).

OEM & ODM projects are highly welcomed. We have strong R&D team here to help.

Your business relationship with us will be confidential to any third party.

Good after-sale service offered, please get back if you got questions.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!