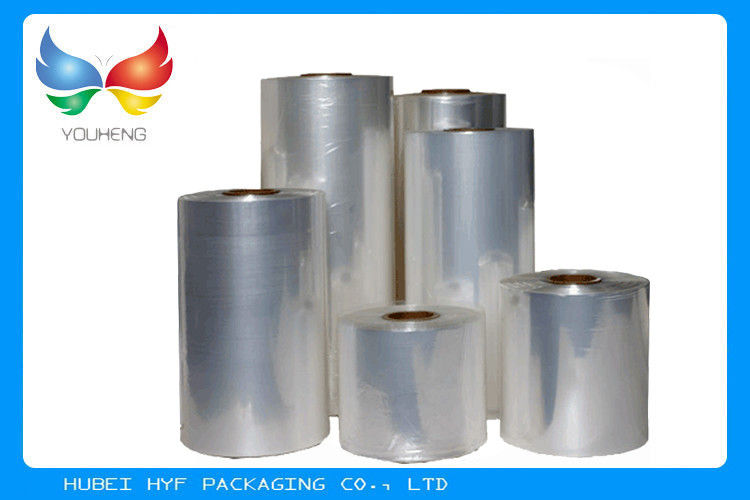

45mic Transparent PVC Sleeve Label Film Rolls for Cans Label

1. Product Description

As consumers become more sophisticated and demand more convenient packaging with higher graphic and visual appeal, packaged consumer goods manufacturers diversify into brands and brand line extensions. Shrink sleeve labels offer packaging technologists, designers, and brand managers high quality aesthetics supporting brand image and recognition.

The ability to label complex geometries offered by the seamed, reverse-printed heat shrink sleeve labels is not possible in any other label type. The Ester Shrink Film can be processed as shrink sleeves which offer the following:

1) Full 360°, wrap around , head-to-toe body decoration creating a unique brand image

2) High quality graphics providing on-shelf product impact

3) Scuff and product resistance of print

4) Provide greatest area for additional information – nutritional, use, contents, safety, etc.

5) Wide range of special effects - matt, gloss, thermo chromic, metallic, pearlescent, fluorescent, etc.

6) Innovative and complex container geometries

7) Integrated tamper-evidence

8) Barrier protection for container and contents

9) Strengthening of container walls

2. Technical Date Sheet Of PVC Shrink Film

| NO. |

Properties |

Unit |

Test Standard |

Test Method |

| 1 |

Width |

mm |

(Order Sheet standard)0-3 |

--- |

| 2 |

Thickness Max tolerance |

% |

±12% |

ASTM D 374 |

| 3 |

Tensile Strength |

MD |

N/mm2 |

≥42 |

ASTM D 882 |

| TD |

N/mm2 |

≥50 |

ASTM D 882 |

| 4 |

Elongation at Break |

MD |

% |

≥70 |

ASTM D 882 |

| TD |

% |

≥50 |

ASTM D 882 |

| 5 |

Shrinkage |

MD |

% |

Order Sheet standard±2.5 |

ASTM D 1204 |

| (100°C,8 Seconds) |

TD |

% |

Order Sheet standard ±2.5 |

ASTM D 1204 |

| 6 |

Friction Coeffcient |

--- |

≤0.5 |

ASTM D 1894E |

3. Containment of breakages

The HYF shrink film offers high shrink rate, making it useful against most of the contoured surfaces. The product also offers excellent slip properties, anti-static characteristic, clarity, and gloss making highly suitable for reverse printing.

It is noteworthy that this product, (unlike PVC Shrink sleeves), is free from chlorine contamination, and is thus being increasingly preferred by environment conscious stakeholders (FMCG's and laminators) and markets.

This film is available in a thickness range of 40-50 microns.

4. Features & Benefits

1) Excellent scratch resistance – reduces the possible abrasion effects while handling & processing

2) Offers high transverse and low machine direction shrinkage at low temperature.

3) Print compatibility with all established printing processes

4) Possess better shrink initiation temperature for ease of storage and transportation condition

5. Applications

The PVC shrink films are used for labeling and packing products in various industries like....

1) Food & beverage industries: Mineral Water, Soft Drinks, Liquors, Pickles, Jams, Jellies, Fruit

2) Juices, Tea, Coffee, Spices, Ghee, Edible Oils etc. In Bottles/Cans/Jars

3) Printing & Packaging industries

4) Cosmetic & Toiletry industries: Powder, Perfume, Hair Oil, Shampoo etc. in bottles & jars

5) Pharmaceutical industries: Liquid Bottles, Tablet/Powder Containers & Jars

6) Electrical industries

7) Stationery & Writing instrument industries

6. FAQ

A1:Do you offer the FOC(Free of charge) sample rolls?

Q1:We offer one roll of 500 meters FOC sample film.

A2:What are the maximum width,thickness and shrinking rate of the products?

Q2:Maximum width 1000mm,maximum thichness 100um,maximum shrink rate 55%.

A3:How long is the producing time?

Q3:The producing time of one container(approximately 25 tons) is 10 days.

A4:What is the expiration date of the products?

Q4:The expiration time is 90 days, by putting in the 25 centigrade warehouse.

A5:How to store?

Q5:The warehouse could be drafty and cool.The AC system is expected.

A6:What is the MOQ(Minimum of quantity)?

Q6:1000 Kg.

A7:What is monthly capacity of the factory?

Q7:1000 Tons.

A8:How to protect the products from heat shrinking during transpotation?

Q8:We always use AC container and thermal-isolating package.

A9:Is it OK for the ten colours high speed printing?

Q9:Yes,it is.

A10:Can I pack the food products by using PVC film directly?

Q10:No.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!